Eucerin’s commitment to sustainable packaging

No navigation available

No navigation available

Plastic pollution is one of the most significant environmental challenges of our time. That is why Eucerin actively supports a circular economy.

However, pollution is not the only issue: it is also a fact that the production of plastic requires finite fossil materials.

For these reasons, we at Eucerin design our packaging to reduce its carbon footprint.

We follow the principles of the 4 R’s: Reduce, Reuse, Recycle, Replace.

We are working on reducing our overall use of plastic packaging. This includes removing unnecessary packaging material and lightweighting the packaging design.That is why the new caps on our Urea, AtopiControl and pH5 hand cream tubes are made with 43% less plastic (compared to the previous tube caps). Using less material also contributes to saving GHG emissions. So, in this case, less really is more.

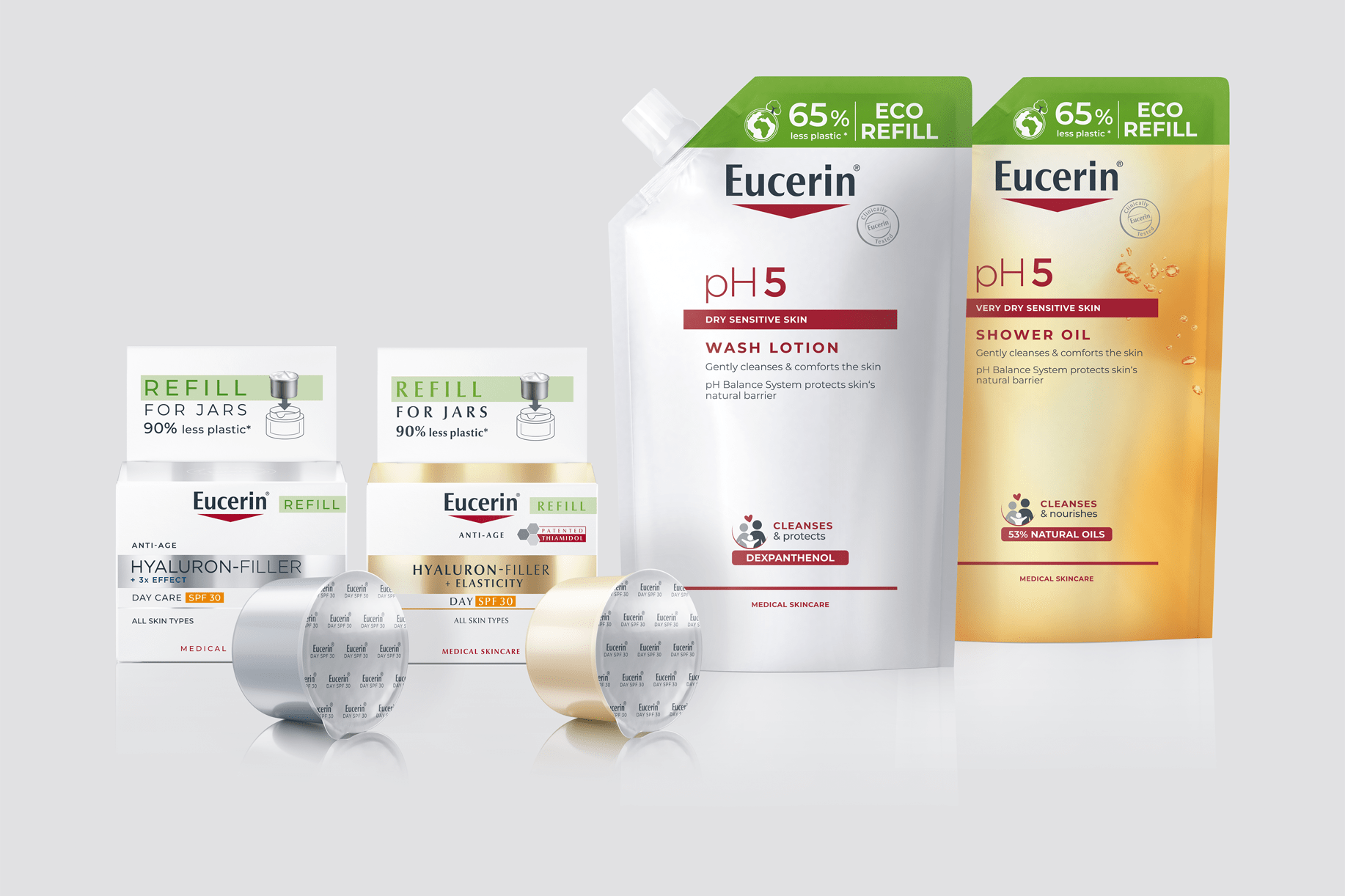

Environmentally speaking, it makes more sense to refill and reuse, so that packaging can have more than one life and become part of a circular economy. Over 20 years ago, we launched our pH5 refill bags. These help consumers refill existing standard bottles and result in 65% less plastic waste compared to a standard 400 ml bottle. Since then, we have expanded our range of packaging formats that can be reused or refilled. Our latest refill innovation is our Eucerin Hyaluron-Filler refill jar using 90% less plastic compared to conventional Hyaluron-Filler jars. Year after year, we will continue to expand our existing refill concepts and introduce innovative refill solutions.

To lower the environmental footprint of our packaging and foster a circular economy, we aim to replace fossil-based virgin plastic with recycled materials. As plastic recycling requires less energy than the production of new materials, we also contribute to reducing GHG emissions in this way. We achieved our first major milestone with our Face Cleanser bottles, which have been made of up to 98% recycled plastic since early 2021. Since then, we have expanded the use of recycled plastic in our packaging across all product ranges. Our Body Cleanser bottles are now made of up to 99% recycled plastic. To actively support a circular economy, we are continuously improving the recyclability of our packaging

On our path to Net Zero 2045, we are continuously working to combine the highest level of product efficacy with a reduced impact on the environment. This work includes the ongoing improvement of our product packaging to find sustainable and formula-friendly solutions for each product. By following the principles of a circular economy, we are striving to significantly reduce greenhouse gas (GHG) emissions.

You can find more detailed information and the current status of our target achievement here: E5 – Resource Use and Circular Economy - Beiersdorf Annual Report 2024